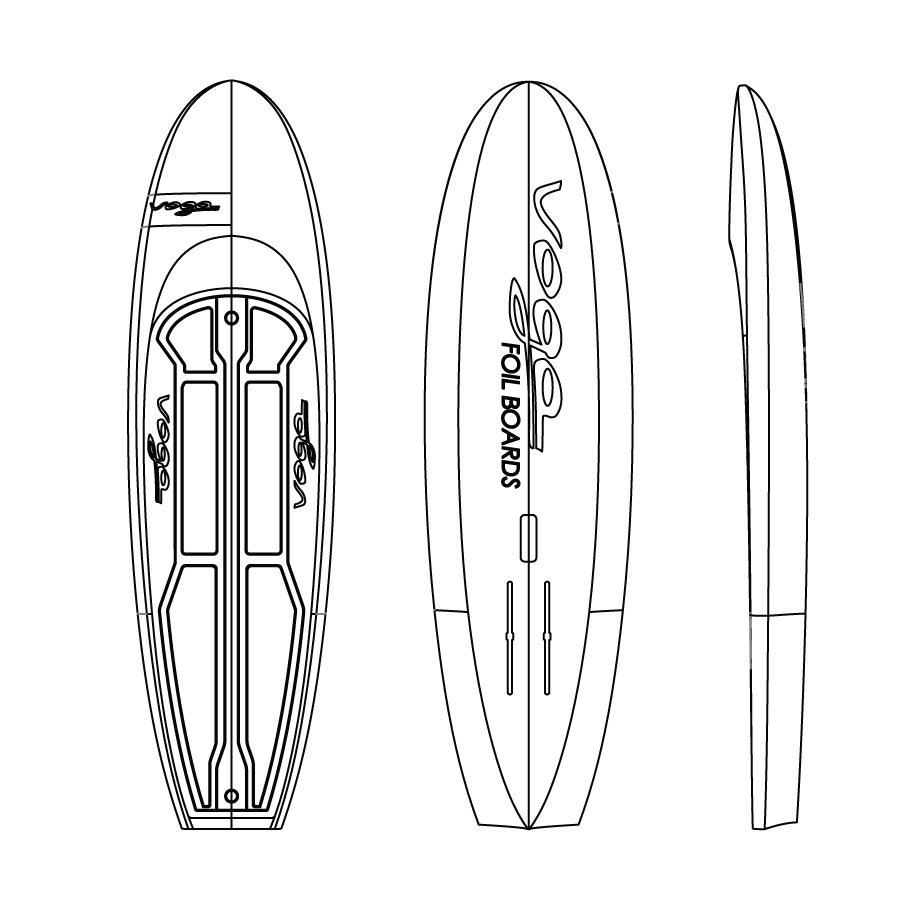

OFFSHORE WING MID-LENGTH | Voga Marine

The Perfect Offshore Companion for Riders Seeking Freedom, Performance, and Style.

Versatility, performance, and comfort.

Designed to fly effortlessly across a wide wind range (7 to 30 knots), the Offshore Wing is the natural evolution of our Offshore line launched in 2023. Tested in all conditions—from the Mediterranean to the Swiss lakes—it has won over both professionals and passionate riders with its intuitive takeoff and incredible stability in flight.

- Ultra-fast takeoff: Its narrow outline, extended length, and minimal wetted surface allow you to glide into flight with the slightest gust.

- Forgiving and smooth: A slight double concave in the front and generous volume cushion touchdowns, making re-launches easier. The Offshore Wing simply doesn’t nose-dive.

- Smart volume: Keeps you afloat and ensures you can paddle back if the wind drops. Its compact size and narrow width also make shore break entries easier.

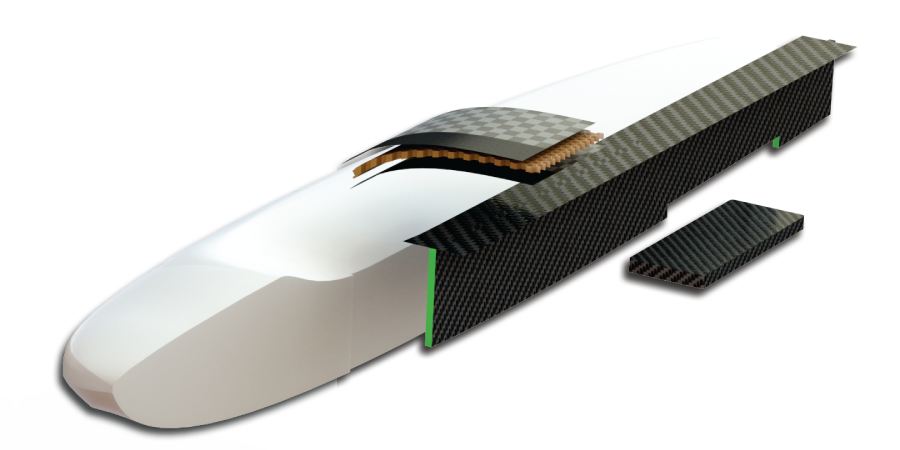

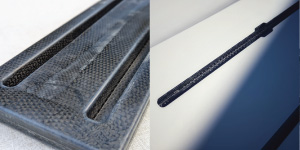

- Premium construction: Built with a PVC carbon/carbon sandwich or honeycomb carbon on ultra-light foam, reinforced with a unique internal structure for exceptional stiffness.

- Pro-level equipment: Comes equipped with our high-performance full carbon US box.

If your were to choose one single board, this would be it.

AVAILABLE FOR TESTING

Starting €1,780.00

Available from PREMIUM-RIDE.STORE by Voga Marine.

Or better yet, contact us directly to customize and order yours.

"A great success, as pleasing to look at as it is to ride. Fluid shape, refined finish — it doesn’t go unnoticed on the beach. On the water, I was blown away by the lightness and responsiveness. I managed to take off in light conditions, despite fickle wind, and with a smaller foil (switching from a 1800 to a 1370). A board that inspires confidence and makes you want to progress."

Features and Options.

| LENGTH | WIDTH | VOLUME | |

|---|---|---|---|

| 6' | 20" | 90L | |

| CUSTOM SIZE 5'10" to 6'5" | 75L to 95L | |||

+ €148.00

+ €68.00

+ €78.00